MASTER ENGINEERING

Warehousing and Storage Solutions Expert

Using Sector:

★ Garment & Textile Industries ★ Food and Beverage Companies

★ Pharmaceutical Industry ★ Tobacco industry ★ Leather Industry

★ Chemical Industry

Selective Pallet Rack:

Selective Pallet Racks, are the most common type of pallet rack systems used today. Selective Pallet Racks usually come in two styles, a roll formed clip-in (teardrop) or structural (bolt-together).

Advantages:

✔ Designed for flexibility and easy access to all pallets.

✔ Can accommodate moving beam levels to different elevations to handle multiple-size pallets.

✔ Easy install and re-configure.

✔ Available in roll-formed or structural steel.

✔ We carry and extensive line of accessories for a variety of applications.

✔ Designed for high-density storage.

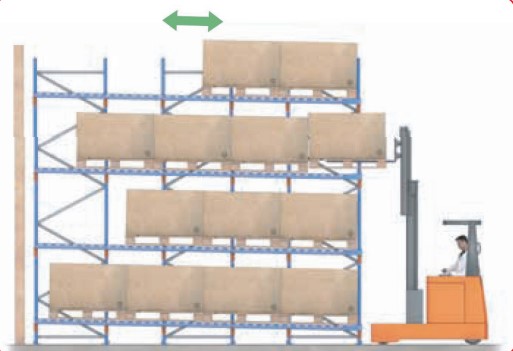

Double Deep Pallet Rack :

Double deep pallet racking systems are the least expensive high-density rack system on the market and here is why: We have more than 7 years of experience in the racking industry. We’ve worked with every type of rack, and we truly mean it when we say we have a rack for every need. Each business has unique needs and which racking system you choose will depend on your storage needs. The double deep pallet racking system might not be right for everyone, but for some, it’s the perfect storage solution. Double deep rack is the only high-density pallet storage rack system that utilizes nothing but low-cost standard selective pallet rack. The only difference is

that it is configured 2 pallets deep, back to back. Therefore you get an extremely dense 4 deep system accessible from both sides, for only the cost of regular uprights and beams. It has a similar density to the drive-in rack but at less cost. What makes a double deep pallet racking system unique is that you place one row of pallet rack behind the other giving you two pallets deep.

Using Sector:

★ Garment & Textile Industries ★ Food and Beverage Companies ★ Pharmaceutical Industry ★ Tobacco industry ★ Leather Industry ★ Chemical Industry

If you have a tremendous number of pallets of the same SKU, double-deep pallet racking systems are for you!

Double deep pallet rack features and benefits:

⌲ Super dense pallet storage

⌲ Lowest cost per pallet position of any rack system

⌲ Increase floor space by 60-65%

⌲ The forklift drive must reach over the first beam level to load and unload pallets off the second beam level

⌲ Very popular rack for high throughput operations

⌲ Optional pallet supports help to support the pallets and give forklift drive confidence when loading back pallets – which decreases the load and pick times

⌲ Requires use of a special 2-deep reach truck

Handling Equipment:

Forklift

Reach Truck

Staeker

Push Back Pallet Rack :

Push Back Rack Systems use gravity-fed telescoping carts to provide high-density storage. As you load the first pallet from the front, its sits on the first cart, and then as you load the second pallet it pushes the first pallet behind its back in one position. This process continues for up to 6 deep. When you want to remove a pallet the fork truck driver lifts the pallet off and reverses slowly and the next pallet comes forward and into the forward position. The front pallet is removed when unloading and the rear pallets automatically come forward to the front picking position. This is considered a LIFO system Last-In-First-Out inventory management. The carts are the low profile which helps in areas with heights restrictions and is all color-coded to make it easy for the driver.

Advantages:

∎ Exceptional use of space.

∎ Allows for both selectivity and dense storage.

∎ Great aisle selectivity.

∎ More picking faces with a small number of aisles.

∎ Available in roll form or structural materials.

Handaling Equpment:

Forklift, Reach Truck, Staeker

Using Sector:

★ Garment & Textile Industries

★ Food and Beverage Companies

★ Pharmaceutical Industry

★ Tobacco industry

★ Leather Industry

★ Chemical Industry

What is Drive-In Drive-Thru Pallet Rack System?

Drive-In/Drive-Through pallet racking systems are a cost-effective solution to high-density storage.

Drive-In/Drive-Through pallet rack is for high-density storage. Drive-in/Drive-Through Rack has specific design criteria that must be considered before deciding whether it is best suited for your warehouse needs. A Drive-In/Drive-Through rack system has rails running the depth of the rack for pallet placement. The only limitation to the depth of the Drive-In/Drive-Through system is the

capability to drive deep within the system

Advantages

High-density storage rack system. Allows for clearance of lift truck as you drive into the rack system. Most cost-effective, high-density storage rack. Multiple configuration possibilities are available in roll form or structural materials. LIFO/FIFO (last in, first out/first in, first out) configurations Reduce space, cut cost, and hold more

loads with its deep lane storage High volume, low SKU Eliminates the need for multiple aisles Provides control over entry and exit Favors density as opposed to the selectivity of Selective Pallet Rack Designed specifically to suit your pallets and forklifts Considerations.

The depth of the system is only restricted by the available space and the quantity and size of the pallets. The height of the system is limited by the height of the building and the maximum lift of the truck and the pallet size. The front column should be reinforced with a double column which will help against damage of trucks. It is critical to have quality wooden pallets where the bottom boards are not damaged and of a consistent size so that they can be safely stored in the system. If pallets are of poor quality a slave pallet should be used for safety.

Using Sector:

★ Garment & Textile Industries ★ Food and Beverage Companies ★ Pharmaceutical Industry ★ Tobacco industry ★ Leather Industry ★ Chemical Industry

Pallet Flow Systems are engineered to perform and manufactured to last. 1 Stop Material Handling offers custom solutions for any application whether it’s economical shallow depth or deep lane flow systems even in harsh environments. Master Engineering understands that properly designed SKU zones will maximize storage capabilities for time-sensitive and consumer goods. Design consideration must account for empty storage space inherited by broken stack loss or honeycombing. the height requirement is unavoidable. Dictated by the required incline, this is especially important in large or deep bay systems.

Advantages

High-Density Storage utilizes space with fewer aisles. First in, First out (FIFO) storage insures product rotation Pick aisle faces are constantly stocked Product flows from the back to the front Aisle frontage is only required at the first location of the supply and discharge ends of the flow lanes.

Using Sector:

★ Garment & Textile Industries ★ Food and Beverage Companies ★ Pharmaceutical Industry ★ Tobacco industry ★ Leather Industry ★ Chemical Industry

A Pallet Shuttle is a compact storage system in which a shuttle (AKA Motorized Cart), driven by an electric motor runs on rails inside the storage channels, replacing forklifts, considerably reducing operating times and enabling items to be grouped by channel rather than in complete lanes. The Pallet Rack Shuttle follows orders sent by an operator using a tablet with a WiFi connection, depositing the load in the first free placement location in the channel and compacting the pallets as much as possible.

By removing the need for forklifts to enter the lanes, storage capacity is increased in terms of depth, the risk of accidents and

damage to the racks is negligible, operator movements are optimized and warehouse operation is modernized and made more flexible. The Radio Shuttle is an ideal solution for companies with a high volume of pallets per item and intensive loading and unloading activity.

Pallet Mole Highlighted benefits:

Greater diversification: each channel can be used to store a different item.

High productivity: increased flow of incoming and outgoing goods.

Greater capacity: Storage depth of up to 131 feet.

Highly cost-effective, thanks to the reduction in operating costs.

Decreased incidents and maintenance costs.

Many advanced functionalities can be

easily controlled from the tablet.

Using Sector:

★ Garment & Textile Industries

★ Food and Beverage Companies

★ Pharmaceutical Industry

★ Tobacco industry

★ Leather Industry

★ Chemical Industry

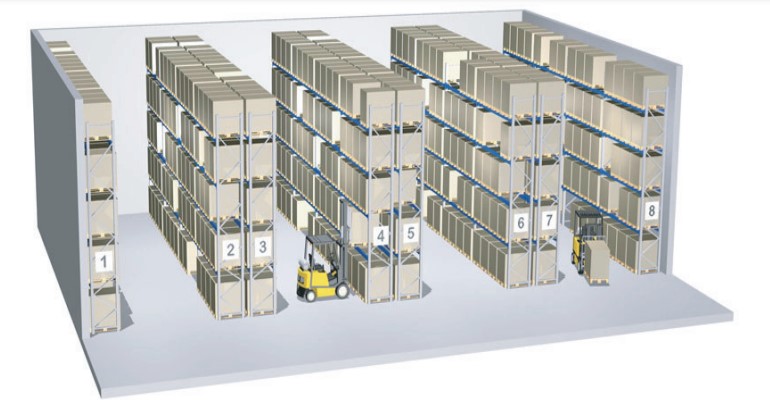

Advantages

∎ Optimal system for cold stores (both refrigeration and freezer types).

∎ Increase in warehouse capacity.

∎ Elimination of individual access aisles.

Using Sector:

★ Garment & Textile Industries ★ Food and Beverage Companies ★ Pharmaceutical Industry ★ Tobacco industry ★ Leather Industry ★ Chemical Industry

With the Movirack system, shelving units become more compact and their storage capacity considerably increased. All this without giving up direct access to any item in stock. The shelving units are installed over guided mobile bases that slide laterally, thus eliminating the need for aisles, which open up only when accessed. The operator gives the order to automatically open the unit, either by remote control or manually by flicking a switch. The mobile bases have motors, sliders, and several safety systems to guarantee a safe and efficient operation.

The automated storage retrieval system commonly known as ASRS or AS/RS is the optimum system for handling boxes for picking. The ASRS system follows the “product to man” concept. The automatic pick system is the ultimate in high-density, high-efficiency storage systems. The mini-load automated warehouse for boxes is made up of a central aisle between two rows of racks. The stacker crane travels down the central aisle and is designed to automatically pick up plastic totes, boxes, trays, or palletized goods. The picking and handling area is made up of conveyors and is positioned at one end or at the side of the racking. The automated storage retrieval system stacker crane deposits the load extracted from the rack.

The conveyors then take the box to the operator. and once he/she has finished the task at hand, it is returned to the stacker crane, which then places it back into the racking.

The whole automated storage retrieval system is controlled by a management software package, which registers the location of all the materials in the warehouse and keeps an inventory in real time. The ASRS system’s extraordinary capacity to adapt enables it to be integrated into any production or storage process.

The ASRS system is made up of four main components:

1. Automated Stacker Crane with Racking – The stacker crane is the device in charge of performing the location and extraction operations of the boxes in the rack system, along with transporting and depositing them in the P&D station of the warehouse. Stacker cranes move in two ways: longitudinally, up and down the aisle guided on a rail, and vertically, when locating the boxes in the different levels and/or depths of the rack.

2. The P&D Station (Picking & Delivery) – The P&D station or the picking and handling area is located at the front side of the racking and performs the mechanical movements to bring the boxes to the operator, or to the stacker crane so that he/she can collect them and put them back in the warehouse. It is made up of a series of conveyors that communicate between work positions and the stacker crane, speeding up the system’s entry and exit of goods. The two systems of transportation are either rollers or belts.

3. Computer Management System- The management system controls all the storage actions, optimizing the time and use of space in the warehouse. Its implementation and level of connectivity make it the perfect tool for the unification of the warehouse with the ERP of the client.

Automated Storage Retrieval System Benefits Include:

∎ Automation of the entry and exit operations of your products.

∎ Savings in storage space.

∎ Elimination of errors arising from the manual management of the warehouse.

∎ Controlling and updating inventory management.

∎ Operating 365 days a year.

∎ Multiplying client service capacity.

∎ Swift payback of the investment.

Using Sector:

★ Garment & Textile Industries

★ Food and Beverage Companies

★ Pharmaceutical Industry

★ Tobacco industry

★ Leather Industry

★ Chemical Industry

Master Engineering Specializes in the design, engineering, sales, and installation of storage systems and material handling products for warehouse.

Address: House-21/8, Khilji Road, Mohammadpur, Dhaka 1207.

All right ressarved masterengineeringbd.com @ 2023 Developed by Freelancer Sohel